*(3) Boring Machines - All 32mm and Through Feed

*(0) Boring Machines - Horizontal; Vertical and other Misc. Non 32mm

*(1) Businesses for Sale

*(0) Carvers

*(0) Chair Equipment

*(4) Clamps - Case Clamps

*(3) Clamps - Clamp Carriers

*(2) Clamps - Door

*(0) Clamps - Drawer

*(0) Clamps - Frame

*(6) CNC Machining Centers - Pod and Rail

*(17) CNC Routers - Flat Table, Nesting

*(1) Combination Machines

*(2) Compressors

*(0) Counter Top Equipment

*(1) Door Equipment

*(0) Dovetailers

*(5) Dowel Machines

*(8) Dust Collectors and Downdraft Tables

*(34) Edgebanders

*(3) End Profilers

*(0) Finger Jointers

*(3) Finishing Equipment

*(0) Fork Lifts

*(0) Glue Equipment

*(1) Jointers

*(2) Laminating Equipment

*(1) Lathes

*(4) Material Handling Equipment

*(2) Miscellaneous

*(0) Mortisers

|

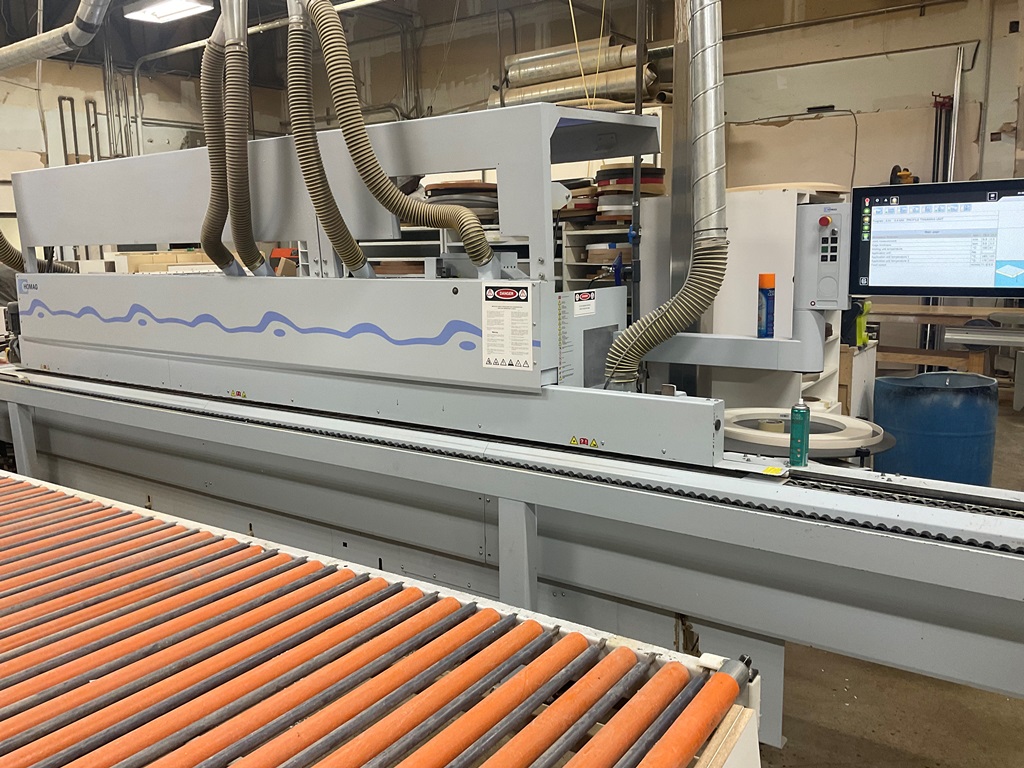

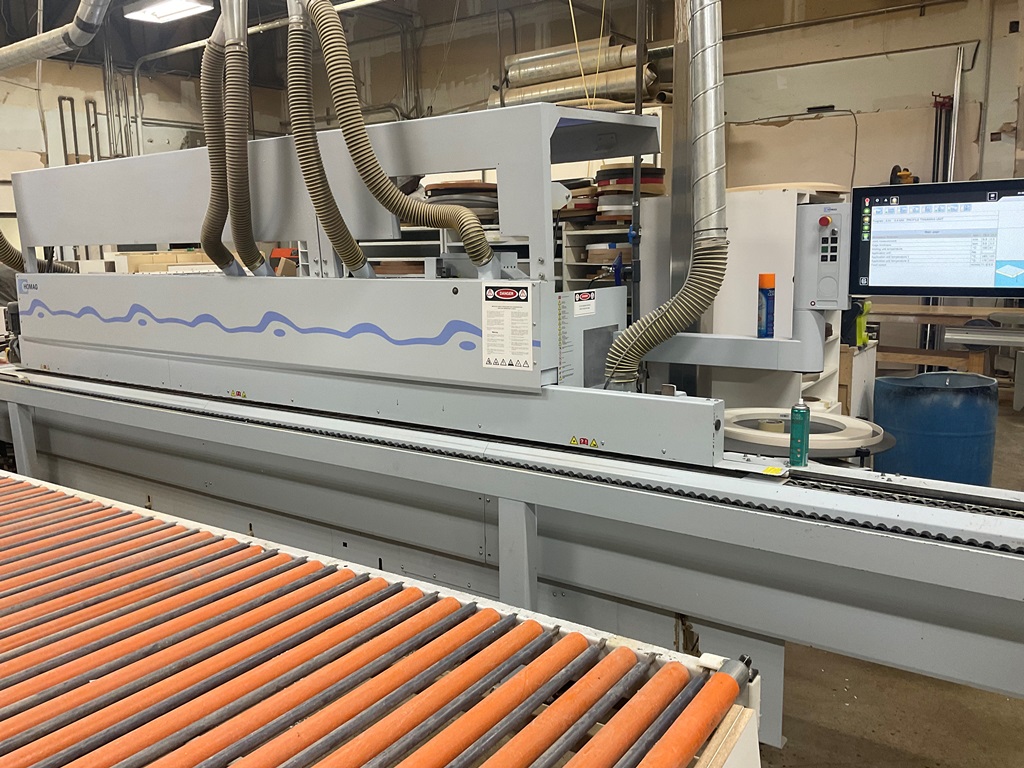

Edgebanders

The edgebanders category includes machines for the application and trimming of edging on wood based, honeycomb or other panels/sheets. The edging ranges from tape as thin as .3mm (0.01") through thicker PVC edging up to 5mm (0.2"), both from continuous coils. Edgebanders also apply veneers and solid wood strip edging up to 30mm (1.2") thick. Edgebanders apply edging to straight edges as well as shaped (softformed) edges. Some have pre-mill heads to prepare the edge for application and some have corner rounding units to end trim shaped (softformed) edges.

|

Biesse Akron 1435A, 2018

|

Biesse Akron 1440A, 2018

|

Biesse Akron 430, 2013

|

Biesse Akron 430, 2014

|

Biesse Akron 440A X, 2008

|

Biesse Jade 240, 2019

|

Biesse Polymac Akron 425 AN, 2007

|

Brandt Brandt O FP 20 corner rounder , 2002

|

Brandt KDF 440 (Highflex 1440), 2013

|

Brandt KDF 650, 2012

JUST RECENTLY REDUCED

|

Brandt Optimat KD 46 with corner rounding, 1996

|

Brandt Optimat KD 67 C, 2002

|

Brandt Optimat KD-56, 2001

|

Brandt Optimat KDN 520, 2005

|

Brandt Optimat KDN 650 C, 2004

|

Brandt Ambition Kal 210 Brandt Ambition Kal 210, 2012

|

Brandt KDF 980 Brandt KDF 980, 2004

|

Cehisa System 4S Cehisa System 4S, 2010

|

Felder Format 4 Tempora Felder Format 4 Tempora,

|

Felder G-400 Felder G-400, 2012

|

Felder Tempora Felder Tempora , 2019

|

Giben KG-450DJ Giben KG-450DJ, 2013

|

Holz-Her Contriga 1368, 2009

|

Holz-Her Sprint 1310, 2005

|

Holz-Her Sprint 1310-1, 2001

|

Holz-Her Sprint 1310-1, 2003

|

Holz-Her Sprint 1320, 2007

|

Holz-Her Triathlon 1487, 2009

|

Homag KDF 440C, 2018

|

SCM Olimpic K1000 ER, 2010

|

SCM K208ER SCM K208ER, 2001

|

SCM Olympic K360 SCM Olympic K360, 2015

|

Tecnoma XTF 10A, 2008

|

VITAP Rounder, 2002

|

Moulders (2)*

Packaging And Shrink Wrapping Equipment (1)*

Pallet Machinery (0)*

Planers - Thickness (6)*

Postformers (0)*

Presses - Hot/Cold (2)*

Presses - Membrane (0)*

Routers - Manual, Pin (0)*

Sanders - DeNibbing and Brush (2)*

Sanders - Edge Stroke (0)*

Sanders - Misc (0)*

Sanders - Planer/Wide Belt (5)*

Sanders - Profile, Mold (0)*

Saw Mill Equipment (0)*

Saws - Band, Resaw (1)*

Saws - CutOff, Miter, Radial Arm (1)*

Saws - Misc (0)*

Saws - Optimizing Cross Cut (0)*

Saws - Panel Beam (12)*

Saws - Rip Saw (8)*

Saws - Sliding Table, Table (3)*

Saws - Vertical Panel (0)*

Shapers (5)*

Sharpening Equipment (2)*

Software (0)*

Stair Equipment (0)*

Stone Machinery (0)*

Tenoners - Double End (0)*

Tenoners - Single, Round End (0)*

Veneer Equipment (0)*

V-Groovers (0)*

Wood Waste Equipment (1)*

|